Introduction:

In India, chikki is one of the most popular desserts and is widely used during various celebrations and festivals. Not only in india, but also from other parts of the world today, this delicious dessert is also very popular. Chikki is a dessert whose main ingredient is raw sugar, so this dish is not too sweet. So for most, how to start a chikki making project in India?

Application:

Chikki is rich in protein, monounsaturated, and has many health benefits.

Fatty acids, antioxidants, minerals and vitamins. It is a good source of calories and is good for your health.

In the Indian Market:

Since the craft of making chikki was relatively simple, the project soon opened up in india. India's functional food industry is strong and a growing force.

International health food market. The health food market is currently estimated at around $1.6 billion and is $75-$10 billion this year.

Different places chikki have different names, just like in China, it is called peanut candy. In other parts of india, it is called Layyiya Patti and Layee. Chikki can be made at home during various festivals. But now, people can start their own chikki making project and make money by producing delicious and delicious chikkis.

What do you need to prepare to start a chikki making project?

Normally, if we prepare chikkis at home during any holiday season, we will not need any special chikki making machines, the production will be small, only for close relatives and dear. However, if you plan to start your own chikkis business, you definitely need a special and advanced machine.

Our company provides chikki making machine in india---fully automatic chikki production line and single machine of chikki production. Choosing the right machine is also often the key to start a successful chikki making project in india.

Fully Automatic Chikki Production Line:

This chikki production machine integrates the three types of cooling, cutting and automatic processing, making production and processing easier and more convenient. Throughout the process, chikki can be mass-produced to better meet market demand. You will be able to produce chikkis of uniform size and quality. By using this machine, the thickness of the chikkis will remain the same. Each machine can produce nearly 300 kg to 500 kg in a short period of time.

Single Machine of Chikki Making Machine in India:

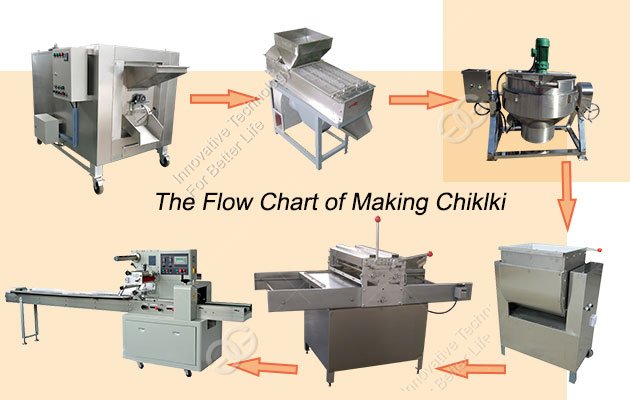

It consists of seven single machines to make chikki

1.Roaster machine: roast peanut to eat directly

2.Peeling machine: to peel the red skin of material, such as peanut.

3.Sugar cooking pot: It is used to melt granuled sugar into paste type. For mixing with raw nuts and crops together to make peanut bars.

4.Mixer: Mix sugar with raw material together uniform for following roller press machine.

5.The forming machine: to reciprocate the stirred material to fill the entire template and compact the material and get your needed shape chikki.

6.Packing machine: it’s used to pack final products into small bags.

However, while we provide you with chikki making machines, we can also help you start a chikki making project in india based on our years of sales experience.

The Working Video of Chikki Making Project: